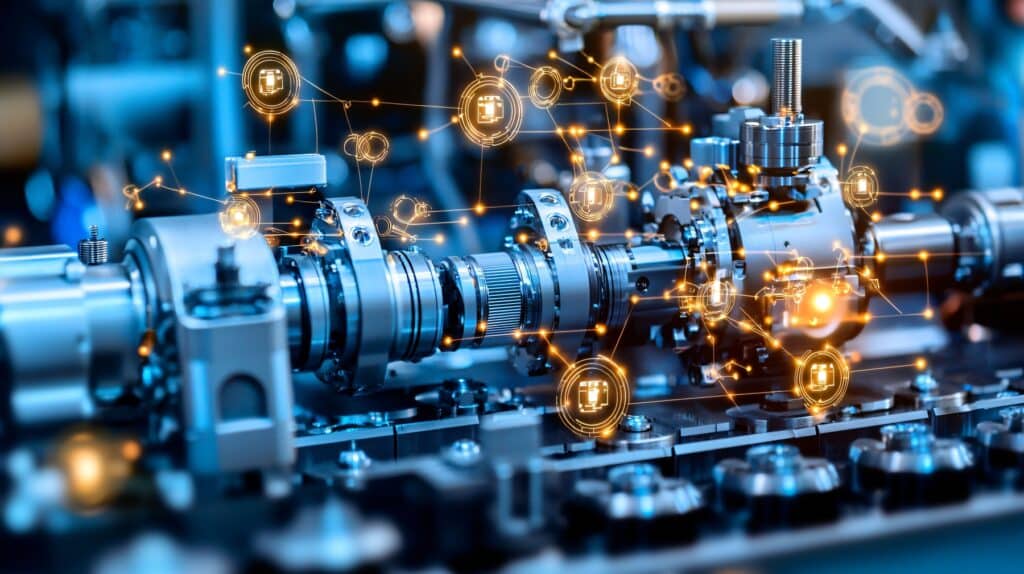

Industrial automation has revolutionized manufacturing, driving productivity and precision to new heights. As industries strive for greater efficiency, integrating advanced technologies becomes essential. From robotics to sensor technologies, various strategies contribute to optimizing automation processes. One such component, Airflow Sensors, plays a pivotal role in ensuring system performance and operational accuracy. Exploring these technologies can provide valuable insights into enhancing your manufacturing operations.

Key Technologies Enhancing Automation Efficiency

Modern industrial automation leverages a multitude of technologies to streamline processes. Robotics, for instance, handle repetitive tasks with high precision, reducing human error and increasing throughput. Programmable Logic Controllers (PLCs) are essential for managing machinery and ensuring synchronized operations. Additionally, Internet of Things (IoT) devices enable real-time monitoring and data collection, facilitating informed decision-making. Integrating these technologies creates a cohesive system that enhances overall efficiency. Moreover, adopting machine learning algorithms can predict maintenance needs, minimizing downtime and optimizing performance.

The Role of Airflow Sensors in Automation

Airflow Sensors are integral to maintaining optimal conditions within automated systems. These sensors monitor the movement and volume of air, ensuring that machinery operates within specified parameters. By providing real-time data, Airflow Sensors help in adjusting processes to maintain efficiency and prevent potential issues. For example, in HVAC systems within manufacturing facilities, these sensors ensure consistent air quality and temperature control, which are critical for both equipment performance and worker safety. Additionally, integrating Airflow Sensors with other IoT devices can enhance predictive maintenance strategies, further reducing downtime and improving system reliability.

Strategies for Optimizing Automation Processes

Optimizing automation processes involves a combination of technology integration and strategic planning. One effective strategy is implementing a centralized control system that oversees all automated operations, ensuring seamless communication between different components. Regular maintenance and calibration of equipment are also crucial to prevent malfunctions and maintain high efficiency. Additionally, training personnel to effectively manage and troubleshoot automated systems can significantly reduce downtime and enhance productivity. Embracing lean manufacturing principles, which focus on minimizing waste and maximizing value, also contributes to more efficient automation processes. By continuously evaluating and refining these strategies, you can achieve sustained improvements in automation efficiency.

Integrating Airflow Sensors for Enhanced Performance

Incorporating Airflow Sensors into your automation setup can significantly boost performance and precision. These sensors provide critical data on air movement, which can be used to fine-tune various processes. For instance, in paint booths, maintaining the right airflow is essential for achieving uniform coating and preventing defects. Airflow Sensors can monitor and adjust the ventilation system to ensure consistent conditions, leading to higher quality outputs. Furthermore, in cleanroom environments, these sensors help maintain the required air purity levels, safeguarding both products and workers. By leveraging the data from Airflow Sensors, you can make informed adjustments that enhance the overall efficiency and reliability of your automated systems.

Importance of Data Integration and Analysis

Data integration and analysis are fundamental to optimizing industrial automation. Collecting data from various sensors, including Airflow Sensors, allows for a comprehensive view of your operations. Advanced analytics tools can process this data to identify patterns, predict potential issues, and recommend improvements. For example, analyzing airflow data alongside temperature and humidity levels can provide insights into environmental conditions that affect machinery performance. Implementing a robust data management system ensures that this information is accessible and actionable, enabling you to make data-driven decisions that enhance efficiency and reduce costs. Embracing big data and analytics is therefore crucial for maintaining a competitive edge in industrial automation.

Implementing Robust Maintenance Practices

Effective maintenance practices are essential for sustaining high levels of automation efficiency. Preventative maintenance, which involves regular inspections and servicing of equipment, helps in identifying and addressing issues before they escalate. Incorporating Airflow Sensors into your maintenance routine allows for continuous monitoring of airflow-related parameters, ensuring that systems remain within optimal operating conditions. Predictive maintenance, powered by data from these sensors, can forecast potential failures and schedule timely interventions, minimizing unexpected downtime. Additionally, maintaining comprehensive maintenance records facilitates better planning and resource allocation, further enhancing the reliability and efficiency of your automated processes.

Frequently Asked Questions

How do Airflow Sensors improve industrial automation?

Airflow Sensors provide real-time data on air movement and volume, allowing for precise adjustments in automated systems to maintain optimal performance and prevent issues.

Can Airflow Sensors integrate with existing automation technologies?

Yes, Airflow Sensors are designed to be compatible with various automation technologies, including IoT devices and PLCs, facilitating seamless integration.

What are the key benefits of using Airflow Sensors in manufacturing?

They enhance system performance, ensure precise operations, improve energy efficiency, and contribute to predictive maintenance strategies.

Are Airflow Sensors difficult to install and maintain?

No, they are generally easy to install and require minimal maintenance, making them a practical addition to most industrial setups.

How do Airflow Sensors contribute to energy efficiency?

By monitoring and optimizing airflow, these sensors help reduce energy consumption in HVAC systems and other air-dependent processes.

What industries can benefit the most from Airflow Sensors?

Industries such as automotive, electronics, pharmaceuticals, and food processing can significantly benefit from the precise airflow management provided by these sensors.

Enhancing industrial automation efficiency requires a multifaceted approach, integrating advanced technologies and strategic practices. Airflow Sensors play a crucial role in this ecosystem, providing essential data that drives informed decision-making and optimizes operations. By embracing these technologies and implementing robust strategies, you can achieve significant improvements in productivity, reliability, and overall efficiency.

Elevate Your Manufacturing Operations Today

Embracing the right technologies and strategies is key to unlocking the full potential of industrial automation. Airflow Sensors, with their ability to provide precise and actionable data, are indispensable tools in this journey. By integrating these sensors into your automation processes, you can ensure optimal performance, reduce downtime, and maintain high-quality standards. Stay ahead of the competition by continuously exploring and adopting innovative solutions that enhance efficiency and drive success in your manufacturing endeavors.

Picture sources:

Oulaphone – stock.adobe.com

DOUGLAS – stock.adobe.com

ModNOy – stock.adobe.com